Gorce Polissage is a French SME recognized for its know-how in sectors as varied and demanding as aeronautics, space, medicine, agrifood, chemicals, petrochemicals and even nuclear. We work with the most demanding standards (Iso 9001, Iso 13485) and use advanced equipment and techniques, know-how.

The number of people in GORCE SAS and at the same time, working with the standards ISO 9001 and 13485, enables us to answer requirements with very high flexibility in terms of lead time, technicality, and capacity (from the unique part to medium or large series).

Our expertise

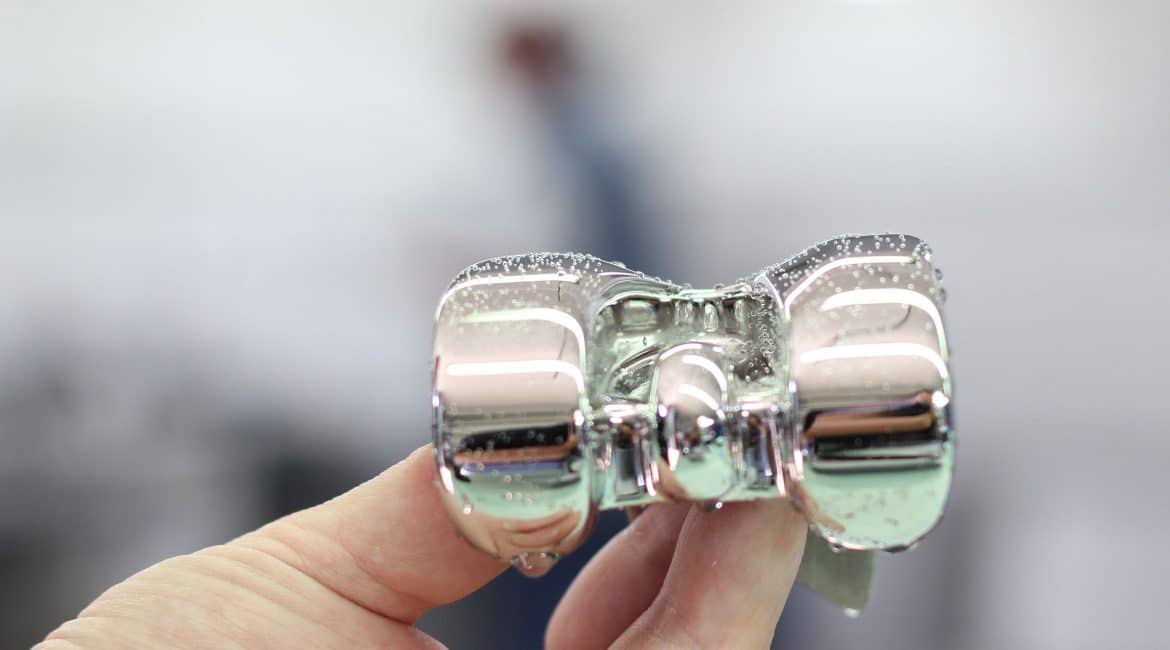

ASTM A967 Medical Passivation

Our company also does passivation process on request. This process consists in removing a part of the iron layer from the surface of the metal part and so it creates a thin protective oxide barrier. By doing so, this leads to a long-life span of protection against corrosion. This method is mandatory for all metals [...]

Polishing

Polishing is a finishing process of parts in all types of material (metal, plastic, wood) with the objective of obtaining a beautiful aspect with a high quality surface finish. Manual polishing Polishing is a finishing process of parts in all types of material (metal, plastic, wood) with the objective of obtaining a beautiful aspect with [...]

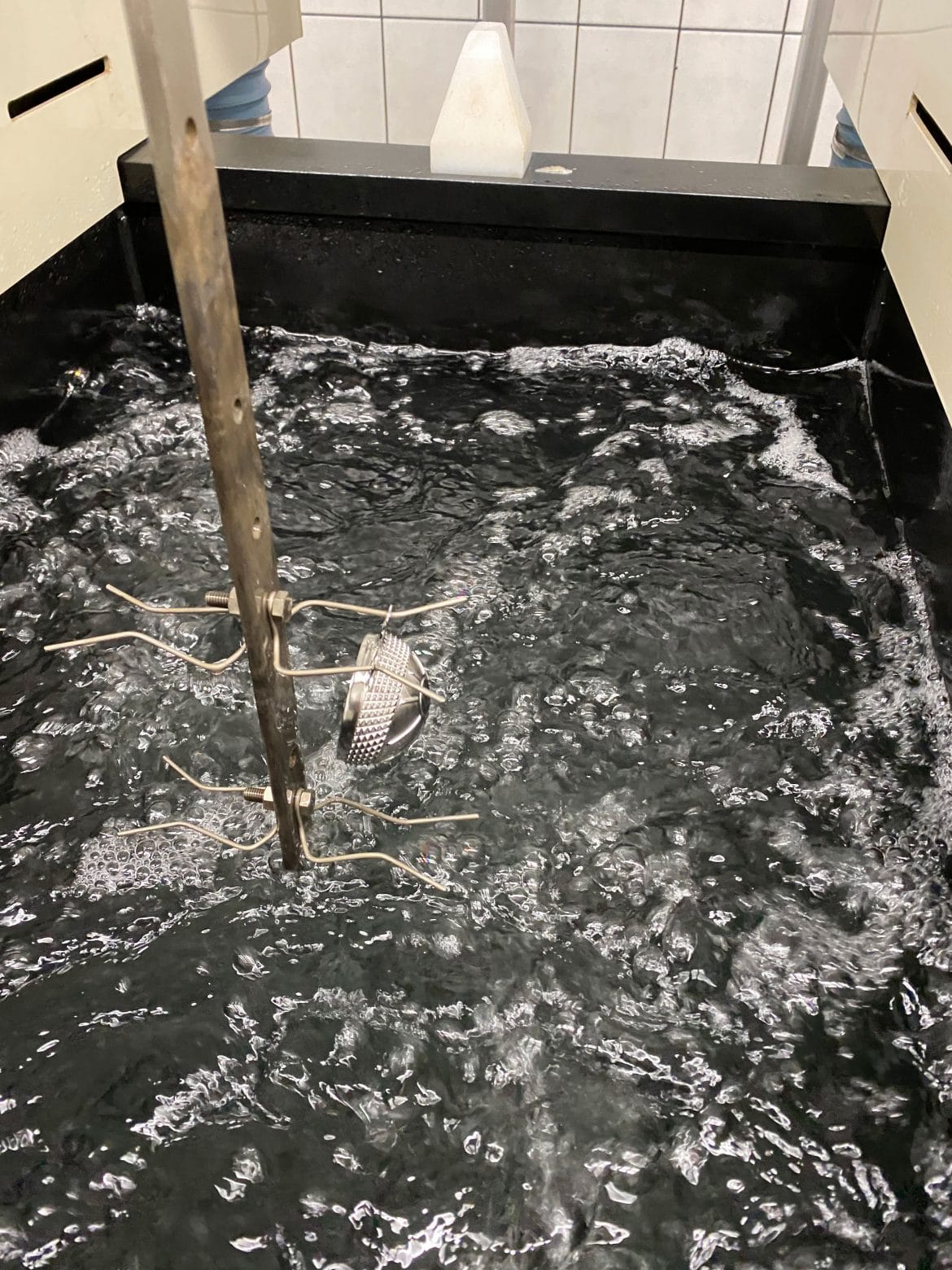

Tribofinishing

Tribofinishing is a technique which enables deburring, polishing and to give a gloss finish. It is specially recommended for medium and large series, and also for small and medium size parts. The principal A vibrator tank in which the parts are mixed with abrasives and different additives according to the desired finish. Equipement Gorce SAS [...]

Laser Etching

Gorce SAS has a laser etching machine which enables them to carry out etching on small and medium series for small and medium size parts. The principal The surface of the part is heated by laser and blackened. This technique assures traceability and identification of the parts Equipement Our machine enables us to etch very [...]

Sand blasting

Sand blasting enables us to strip, remove polish, de-oxidise, giving a roughness, smoothness and to prepare the surface before painting. The term sanding comes from the fact that originally sand was used as an abrasive. The principal Sanding is an industrial cleaning technique for surfaces by using a high speed projected abrasive on the material. [...]

Cleaning

According to the sector of activity, cleaning must be carried out to the customer’s requirements. For the medical sectors for example, we must return the parts extremely clean. The principal The parts are dipped in different tanks for a certain length of time which cleans them completely and removes any trace of polishing paste. Equipement [...]